As electric vehicles (EVs) gain popularity, engineers are rethinking nearly every aspect of traditional car design — including the suspension system. While the core function of a suspension system remains unchanged (ensuring ride comfort, handling, and safety), EVs introduce unique design considerations that make their suspension setups fundamentally different from those in internal combustion engine (ICE) vehicles.

In this article, we’ll explore how and why suspension systems are evolving to meet the demands of electric vehicles. We’ll also compare them to conventional systems, highlight component changes, and discuss what it means for drivers and maintenance.

What Does a Suspension System Do?

At its core, a suspension system serves to:

-

Absorb road shocks and vibrations

-

Maintain tire contact with the road

-

Control vehicle handling and stability

-

Support vehicle weight and balance

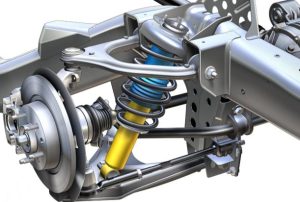

Whether in ICE or electric vehicles, the suspension system includes components like springs, dampers (shock absorbers), control arms, bushings, sway bars, and subframes.

What’s Different in EV Suspensions?

Electric vehicles require adapted suspension systems due to the following factors:

1. Battery Pack Weight and Placement

EVs are significantly heavier than ICE vehicles because of large battery packs, which can weigh 300–600 kg and are typically mounted low and across the vehicle’s floor (skateboard design). This results in a low center of gravity, but also higher unsprung weight on the suspension system.

2. Weight Distribution

With no heavy engine in the front, EVs often achieve near 50/50 weight distribution. This alters suspension tuning because weight transfer during acceleration, braking, and cornering is different compared to front-heavy ICE vehicles.

3. Instant Torque Delivery

Electric motors provide immediate torque, putting more stress on suspension components during acceleration. This demands stronger bushings, control arms, and dampers to handle increased torque loads and resist squatting.

4. Quieter Operation

EVs operate more quietly, which exposes suspension noise like creaks and rattles that may have gone unnoticed in ICE vehicles. As a result, EV suspensions are designed with extra noise-dampening features such as foam-filled bushings and isolated subframes.

Comparison Table: EV vs ICE Suspension Systems

| Feature | EV Suspension | ICE Suspension |

|---|---|---|

| Vehicle Weight | Heavier due to battery | Lighter overall |

| Weight Distribution | Evenly balanced (50/50) | Often front-heavy |

| Torque Delivery | Instant, high torque | Gradual torque buildup |

| Center of Gravity | Very low (battery floor-mounted) | Higher (engine above axle) |

| Suspension Tuning | Requires stiffer damping and spring rates | Conventional tuning sufficient |

| Noise Suppression | Enhanced to reduce cabin noise | Standard rubber bushings |

Key Suspension Components Modified for EVs

1. Stronger Control Arms

-

Built to handle extra torque and mass

-

Often made of high-strength steel or lightweight aluminum

2. Upgraded Shock Absorbers

-

Tuned for heavier curb weights

-

Advanced electronic damping in many EVs

3. Thicker Anti-Roll Bars

-

Added to counteract increased body roll due to higher mass

4. Noise-Isolating Bushings

-

Multi-layer or fluid-filled to dampen vibration and noise

5. Adaptive or Air Suspension

-

Common in premium EVs for customizable ride quality

Suspension Types Used in EVs

| Suspension Type | Common Usage in EVs | Benefit |

|---|---|---|

| MacPherson Strut (Front) | Most compact EVs | Simple, space-efficient |

| Multi-Link (Rear) | Premium & performance EVs | Enhanced comfort and handling |

| Air Suspension | Luxury EVs (e.g., Tesla, Audi) | Adjustable ride height, smooth ride |

| Coil Spring with Dampers | Entry-level EVs | Cost-effective, adequate for normal driving |

Smart Suspension Systems in EVs

Modern electric vehicles increasingly feature active or semi-active suspensions that dynamically adapt to driving conditions:

-

Electronic Damping Control (EDC): Adjusts shock absorber stiffness in real-time.

-

Self-leveling Air Suspension: Maintains ride height regardless of load.

-

Predictive Road Scanning: Uses sensors or cameras to anticipate road irregularities and adjust accordingly (e.g., Mercedes E-Active Body Control).

Maintenance Considerations for EV Suspension

Despite fewer moving drivetrain parts, EV suspensions can wear faster in some cases due to heavier weight and torque. Here’s what owners should watch for:

Common Wear Points in EV Suspensions:

-

Bushings: Prone to early wear due to added stress

-

Ball Joints: Extra weight shortens lifespan

-

Control Arms: May develop play under torque load

-

Shocks/Struts: More susceptible to fade or oil leaks

When to Inspect:

-

Every 15,000–20,000 km for basic checks

-

After hitting potholes or curbs

-

If you notice increased cabin noise, uneven tire wear, or poor handling

Need replacement parts?

Buy Suspension online — Explore a full range of control arms, bushings, dampers, and EV-compatible suspension components.

EV Suspension Tuning for Performance

Performance EVs like the Tesla Model S Plaid or Porsche Taycan require precision-tuned suspension systems to manage instant torque and high speeds.

Tuning Goals for EVs:

-

Enhance body control during fast launches

-

Minimize squat and dive

-

Maintain tire contact under lateral loads

-

Reduce body roll without compromising comfort

EV-specific coilovers, sway bars, and polyurethane bushings are often used in custom or track builds.

Advantages of EV-Specific Suspension Design

-

Better handling due to low center of gravity

-

Improved ride comfort with air or adaptive systems

-

Quieter, smoother operation

-

Less body roll in most configurations

Future Trends: What’s Coming?

With EVs evolving rapidly, suspension technology is also advancing:

-

Solid-state dampers using magnetorheological fluids

-

Predictive AI suspension control for terrain adaptation

-

Integrated drivetrain-suspension modules to reduce weight

-

3D-printed suspension components for customized geometry

Conclusion: Suspension Matters More Than Ever

While EVs are revolutionizing the automotive industry, they’re also redefining suspension design. Their unique weight distribution, torque characteristics, and quiet operation require suspension systems that are more robust, refined, and adaptive than ever before.

Whether you drive a compact EV or a high-performance electric sedan, ensuring your suspension system is in top shape is key to enjoying a smooth, controlled, and efficient ride.

Upgrading or replacing components?

Buy Suspension online — Get premium-quality parts designed for today’s advanced electric vehicles.